Calendrics — the science (and art) of calendar creation — can be fun. Our traditional timekeeping system includes various units of time: seconds, minutes, hours, days, weeks, months, and years — but not all of these correspond to observable phenomena or always line up nicely with each other.

Each February 29th provides a nice opportunity to take a step back and look at the specifics of the current Western calendar — the “Gregorian calendar.” Our current calendar is a subtle-but-important modification of the previous (Julian) calendar. The modifications, made by Pope Gregory XIII, no doubt on the advice of astronomers, were designed to make a one-time correction to the calendar to realign dates with their proper respective seasons, and to make a subtle lasting change to the number of leap years so that the calendar would not continue to drift (at least as rapidly).

We define a solar day as the time it takes for the sun to return to the same apparent position in the sky. It takes a bit more than 365 of these solar days (one tropical year) for the Earth to go around the Sun once, returning the Sun to the same apparent place with respect to the background of stars. With just basic astronomical observations over the course of a few years, it was determined in antiquity that every fourth year needed to be one day longer to keep things in sync. This, plus the almost-but-not-quite-even splitting up of the year into the months we are familiar with, became the Julian calendar (named after Julius Caesar).

The Julian calendar worked fairly well, but by 1582, the year was some ten days out of sync: the equinoxes occurred some ten days earlier than their traditional, expected time. The Gregorian calendar, implemented by fiat by Pope Gregory and slowly adopted by non-Catholic nations (since it also happened to make good mathematical sense), subtly modified the Julian calendar as follows:

- Every year divisible by four is a leap year, except

- Every year divisible by 100 is not a leap year, except

- Every year divisible by 400 is a leap year.

Therefore, 1900 was not a leap year, but 2000 was. (There won’t be another millennial leap year until the year 4000.)

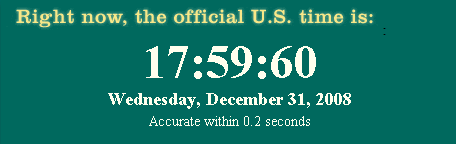

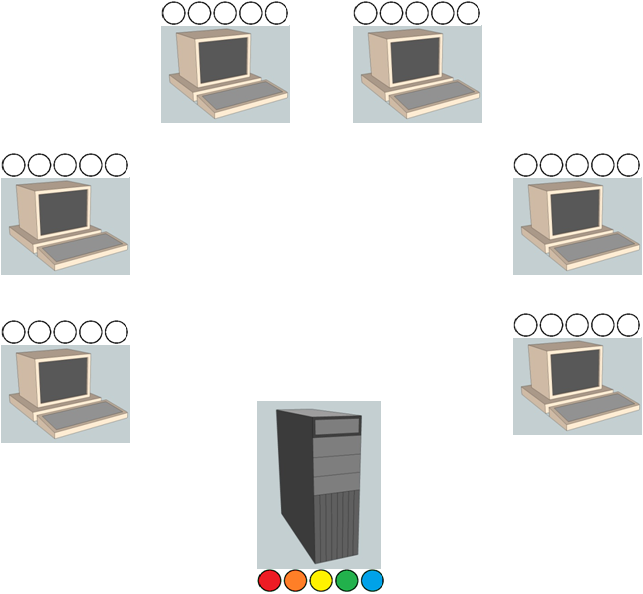

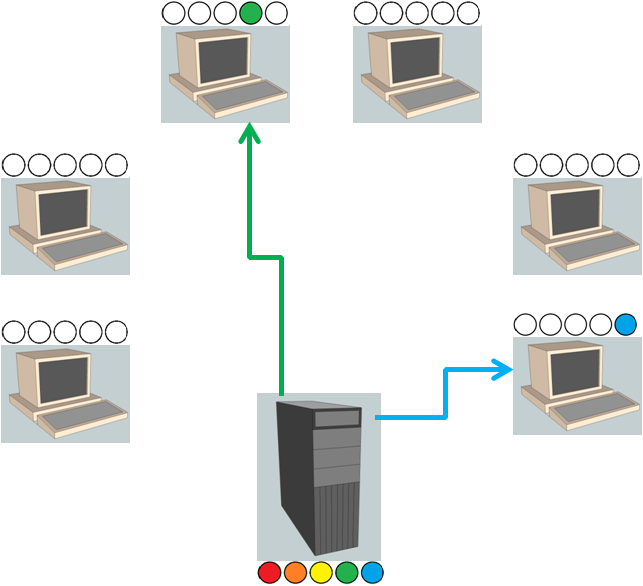

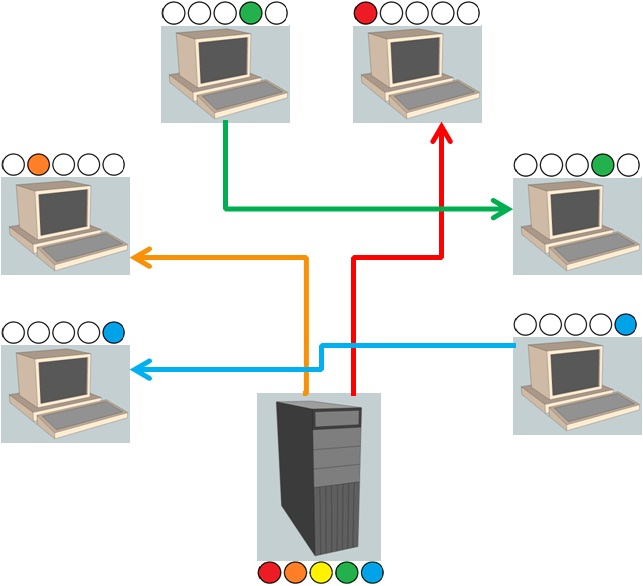

This scheme keeps the calendar closely enough in step with the Earth’s movement through space that the largest errors are now due to the gradual slowing of the Earth’s rotation. This has led to the modern (and somewhat controversial) practice of adding “leap seconds” to civil time, as required by variations in the Earth’s rotation. Leap seconds work similarly to leap days: every so often, the final minute of June 30 and/or December 31 is lengthened by one second: 23:59:58 –> 23:59:59 –> 23:59:60 –> 00:00:00 .

As for me, I’m definitely in favor of leap seconds. They’re a nice solution to the problem of small-scale calendric drift, and add a bit of statistical excitement to the subject, as well. If the Powers That Be are in an abolitionary mood, though, they could always do us a favor and get rid of Daylight Saving Time.