The first computer I ever used was a university mainframe, accessed through a teletype terminal in my uncle’s apartment. It played a mean game of Tic-Tac-Toe (and presumably helped with my uncle’s Finance dissertation.)

The second computer I ever used, the first one I ever owned, and the one on which I learned all kinds of horrible 1980s-BASIC programming habits on, was a Timex-Sinclair 1000.

The Timex-Sinclair 1000. (Thanks, Mom and Dad. Best present ever!)

The TS1000 had the distinction of being the first home computer under the magical $100 mark. While still not cheap, that put it within reach of normal people. The Personal Computer revolution was beginning!

The TS1000 is based on the deservedly popular Z80 microprocessor. Sinclair Research combined the Z80 with a custom video card, a ROM containing the BASIC programming language, and 2KB of RAM.

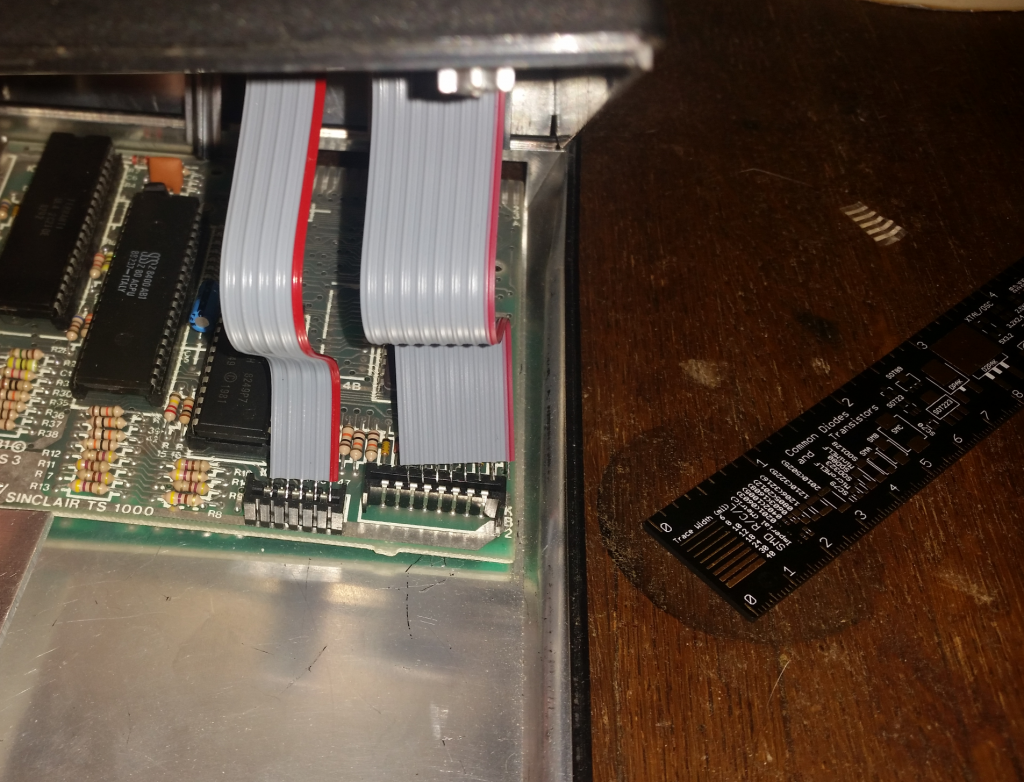

The Timex-Sinclair 1000 system board.

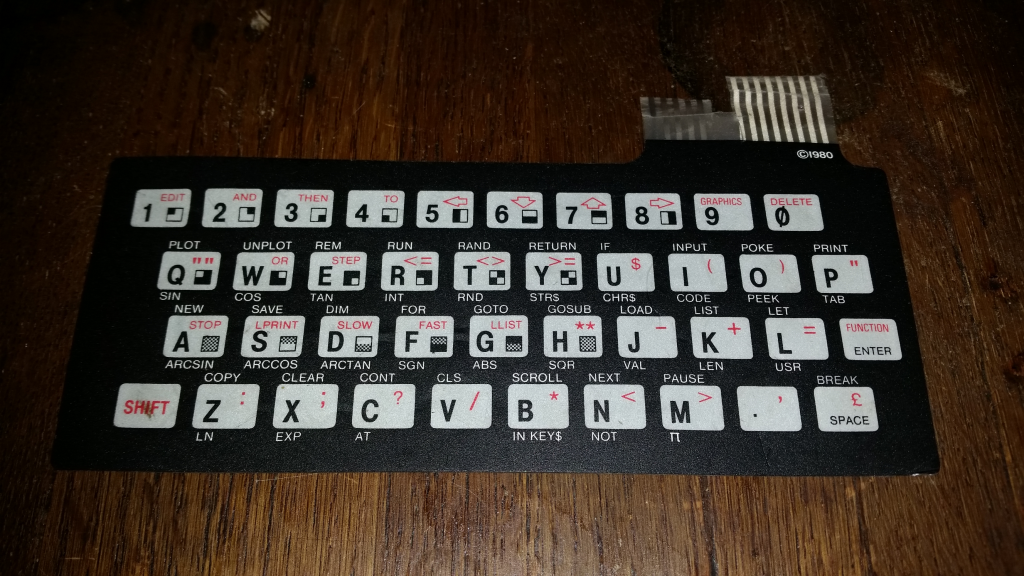

The keyboard no doubt contributed to the low cost of the Sinclair, as it was a very cheaply manufactured membrane keyboard which connected through a slit in the top case to plug onto the system board. These worked marginally well for a few years, but would inevitably become brittle with age. When this happened, the conductors would develop hairline cracks. If even one of the thirteen keyboard lines broke completely, a whole section of the keyboard would become unresponsive. It’s rare to see one working these days. Neither of my two did…

My original keyboard, showing the deteriorated connector.

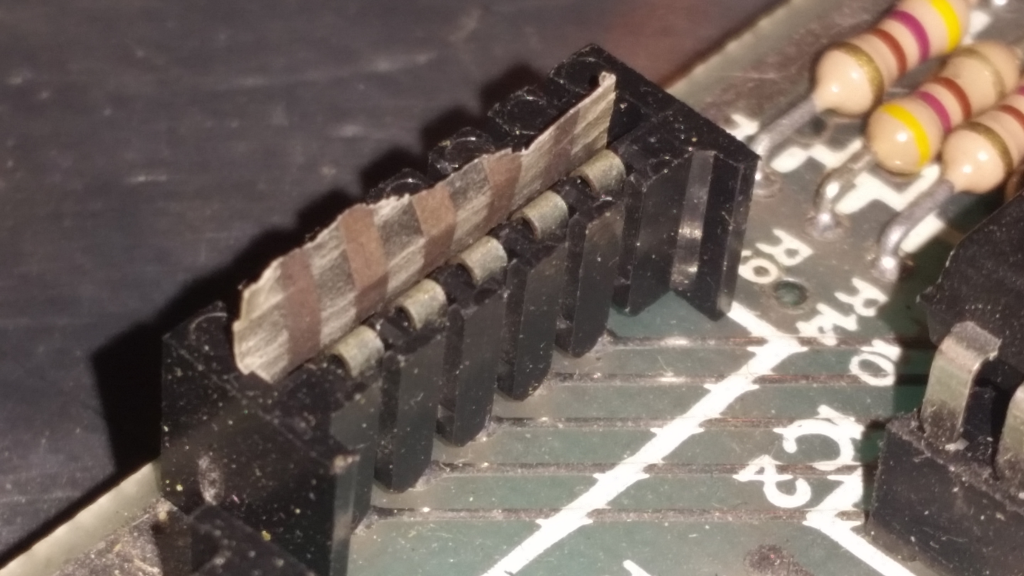

Not only did these old keyboard connectors break — they would often break off in the connector, requiring exploratory surgery to clear them out before the connector could be inspected, cut cleanly before the break, and hopefully reinserted if it hadn’t become too short.

That’s not supposed to be there. Not without the rest of it, anyway.

Fortunately, it came right out.

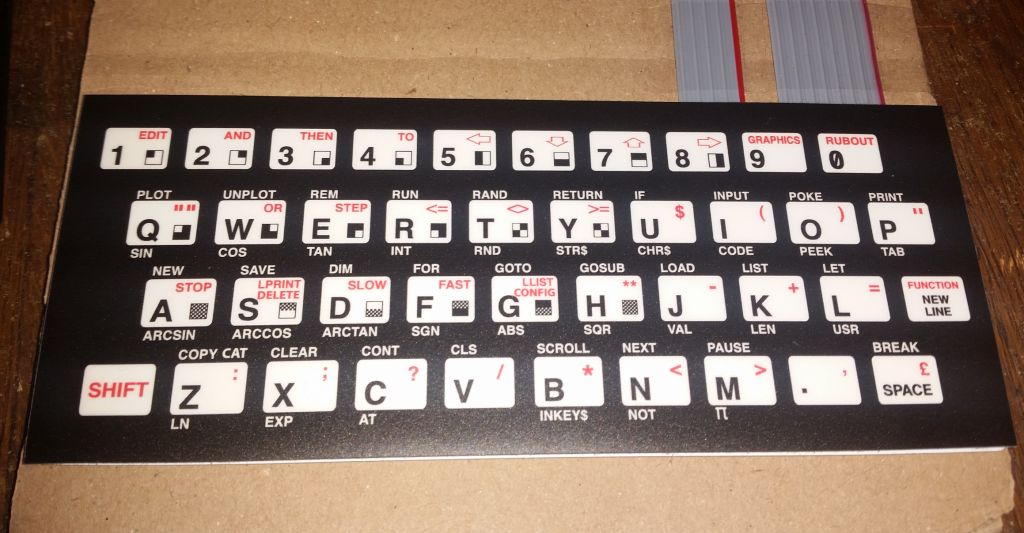

Nostalgia being what it is, many of my fellow middle-age geeks fondly remember the Sinclair, keyboard problems and all. So I guess it’s not surprising that someone came up with a solution. I found a site selling replacement ZX81/TS1000 keyboards for about $15 or so. Not a bad price at all to resurrect an old (if temperamental) friend!

The new keyboard.

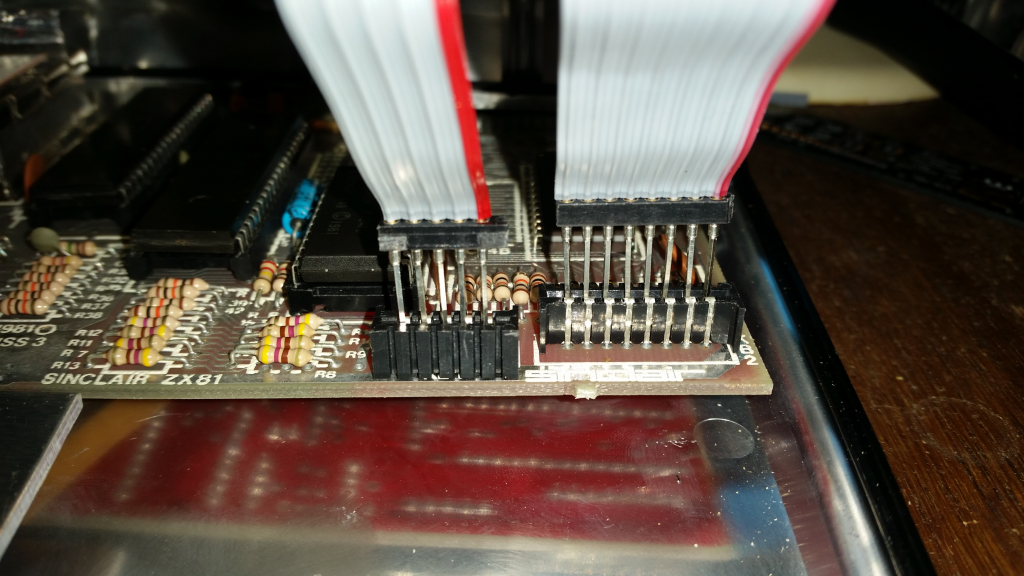

A few weeks later, the keyboard arrived. The key action is much better than the original, but the tinned metal connectors on the end appear to be intended for soldering rather than for plugging into the keyboard connector.

Tinned wire connections on the new keyboard. Good for soldering, not so good for staying in the old socket.

Never one to design an engineered solution when a perfectly good hack would do, I cut up a wire-wrap socket (probably half as expensive as the keyboard — they’re Not Cheap). It’s not going anywhere, now.

A hacked-up wire-wrap socket works perfectly.

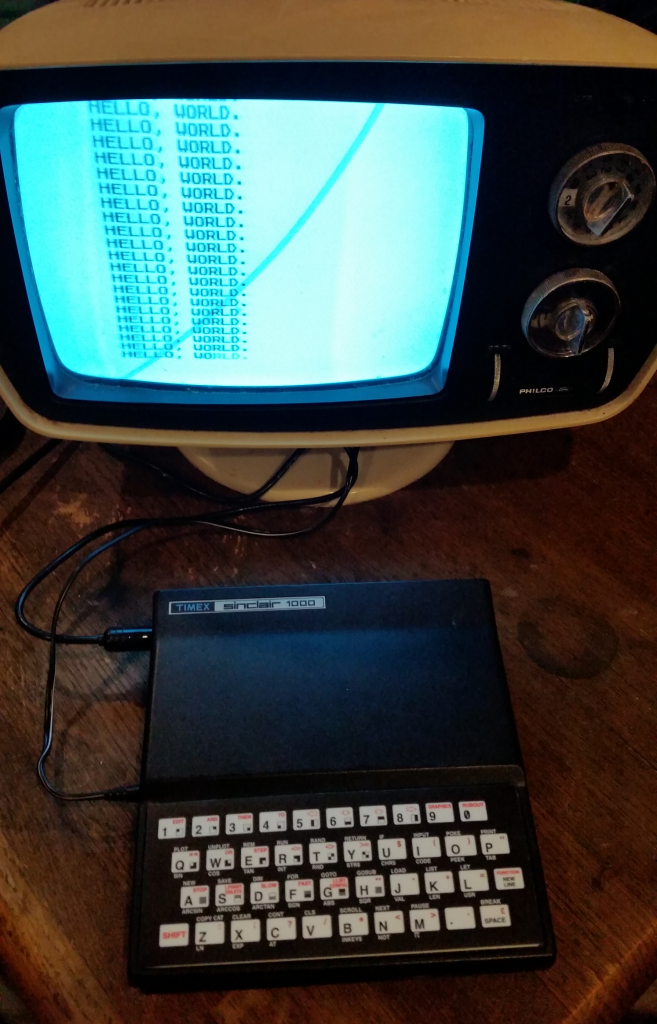

With the new keyboard, the Sinclair is back from the dead! Now to fix up the case a bit and work on some peripherals — or at least a way to save and load programs from an mp3 player or something.

It’s alive! (And so is the 1970 Ford TV that I used to use with it.)