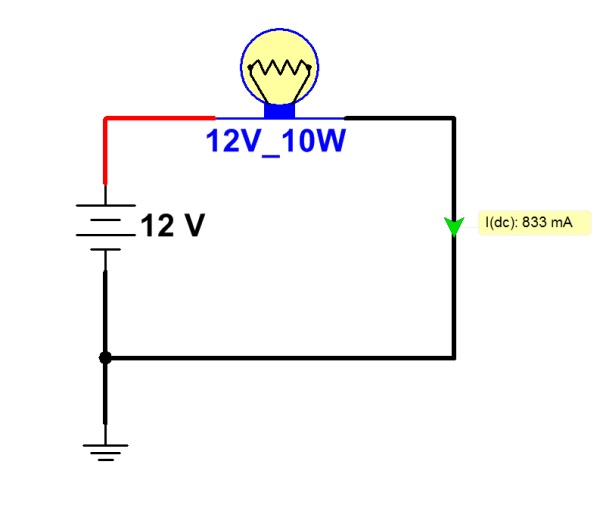

Perhaps the most basic form of electronic security system involves a buzzer or bell set to go off if a loop of wire is cut. Sensors, such as door position switches and sliding window contacts, can be inserted into this loop, breaking the circuit if a window or door is opened. When the loop is cut (say, by a window switch opening), an alarm bell can be made to ring.

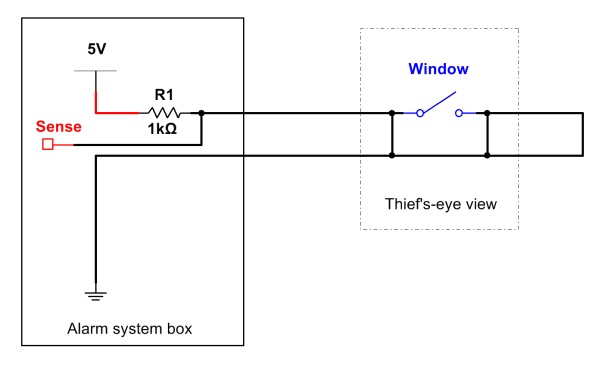

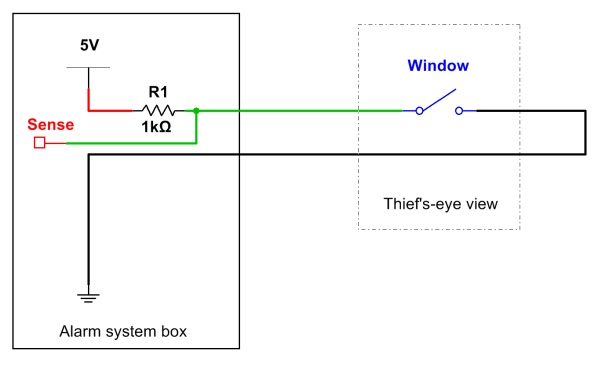

This simple approach, though effective, has a weakness. If a nefarious individual wished to circumvent this protection, he or she need only expose a section of cable, short it in two places (who knows which side of the wire goes to the alarm), and then cut it between the two shorts. Whether the security system was on the right or left side of the cut, the loop would still be complete, and current would still flow. Make these shorts on either side of a door or window sensor, and you can then open the door or window without triggering the alarm. In addition, all of the sensors “downstream” of the cut are now taken out of action.

First, the thief shorts the wire on both sides of the switch (he doesn’t know which end goes to the alarm system)…

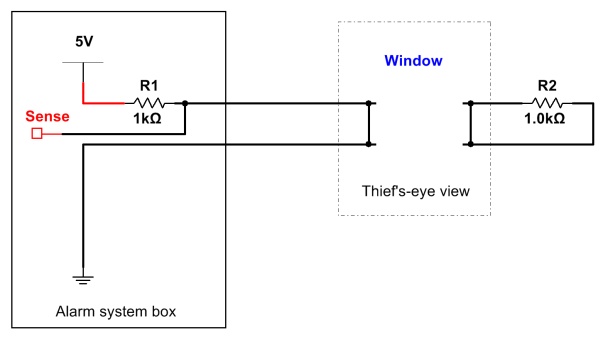

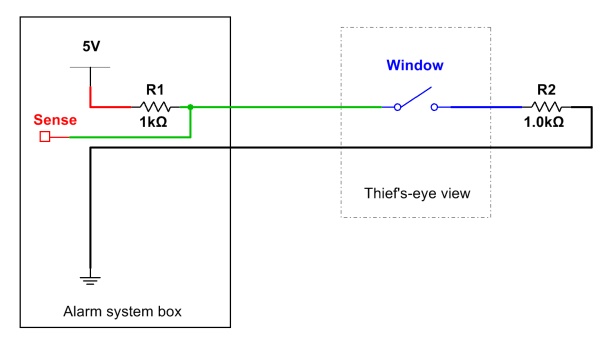

What can be done to detect such dastardly meddling? Plenty. Rather than making a simple current loop, an end-of-loop resistor can be incorporated, and the system set to monitor the loop for a specific expected resistance. Any would-be burglar would then have to not just short the cable, but provide the appropriate resistance. Without prior knowledge of the system, this would be essentially impossible; it would be quite tricky even if given a schematic, wiring layout diagrams, and a good portable electronics lab. Even if the correct resistance (and direction to the control box) were known, inserting a fake end-of-loop resistor while maintaining a constant line resistance would be very difficult.

Here, a thief has tried to defeat the added-resistor system, but the electronics sense a dead short and trigger a tamper alarm. ARF ARF — GOTCHA! (Click for larger.)

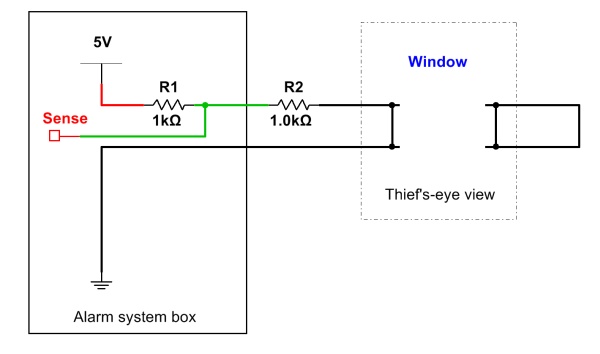

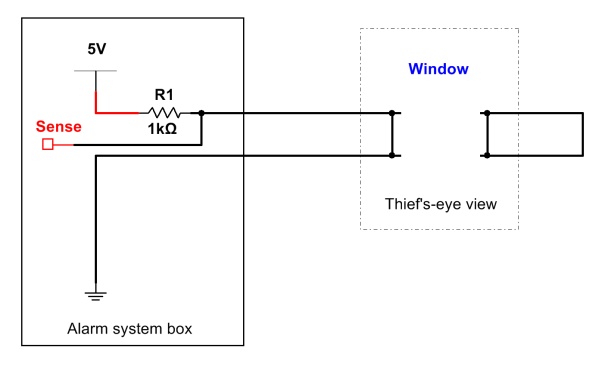

However, a security system is only as good as its weakest link –including the installer. Loop resistors do not, by themselves, somehow imbue the wire with magical properties which make it immune to tampering. If placed at the near end of the loop (I.E. in the box), the loop resistors add nothing to the system security. Whether the wire is shorted or not, the resistance will always be there.

Even with the resistor in the loop, the thief can safely disable this system with the simple shorting technique. Moral of the story: don’t put your loop resistances right at the box. (Click for larger.)

In other words, this is how it’s not done:

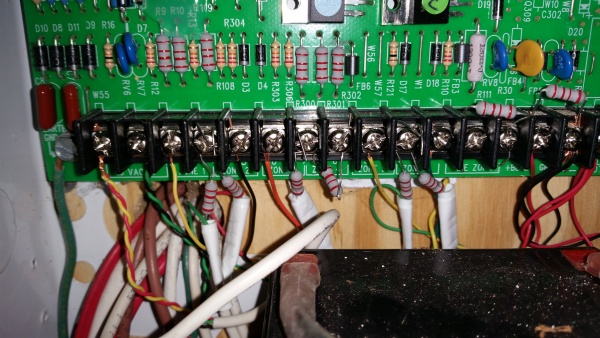

Loop resistances done wrong. Those 2.2k resistors (red/red/red) should be at the far end of the loop. (Click for larger.)

Note to self: Re-wire security system the right way.

![These are cheap, useful, and easy to work with... [16x2 LCD display]](https://www.paleotechnologist.net/wp-content/uploads/2014/04/lcd_sm.jpg)