As part of a recent Girls, Inc. summer camp activity we hosted at work, I designed and produced about a dozen Electronic Mood Rings. This turned out to be a learning experience in many ways.

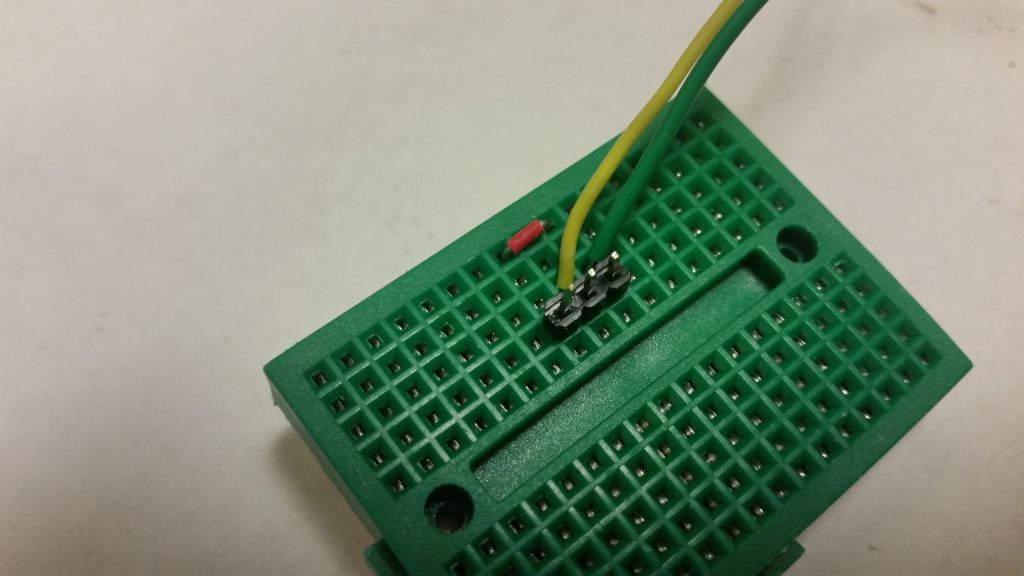

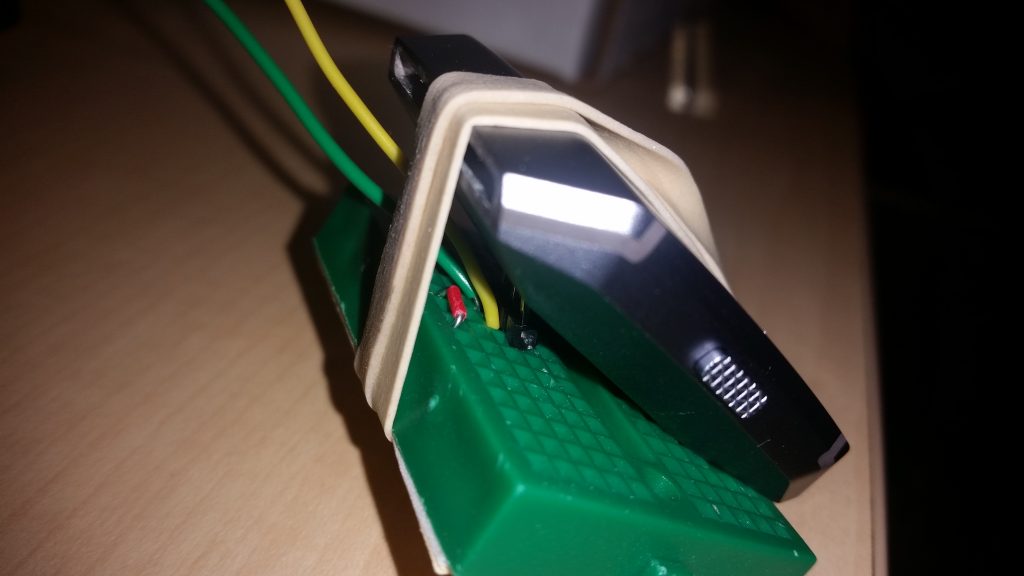

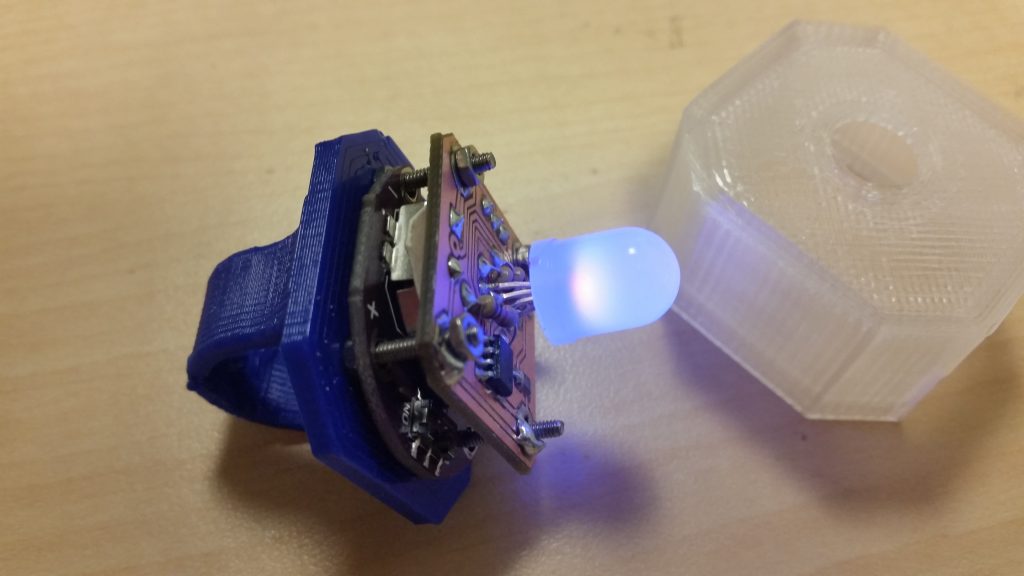

The prototype Electronic Mood Ring.

I learned that, while SMT devices are tricky to work with, SOIC parts can be reasoned with if you use a good iron, silver-bearing solder, and generous amounts of flux.

I learned that 1206 SMT parts are very forgiving but still a pain to solder by hand. Stencils and reflow may be the way to go, here. Or just outsourcing it.

I learned that PIC12F1571 microcontrollers should be able to run at 32MHz internal clock speed. Nice! Except that mine didn’t want to turn the PLL on, and I had to settle for 16MHz because it was easier than continuing to argue the point. Besides, the new BRW instruction means no more mucking about making sure my computed GOTO tables don’t cross 8-bit boundaries. So I can forgive a few quirks.

I learned that I still don’t know how to solder true SMT parts such as NeoPixel Mini PCBs. Might need a reflow plate for those.

I learned that, for whatever reason, clear PLA filament just will not print reliably on my machine. Purple printed fine. Pink printed fine. Blue printed fine. Even black cooperated and printed without problems, which isn’t always a sure thing. But three different reputable brands of clear filament caused 95% of the problems. It jammed. It blobbed. It strung. It refused to adhere to the bed at one point.

Bizarre.

I also learned not to trust knockoff parts. The battery holders I bought only worked properly once I figured out you need to wedge a strip of aluminum foil under the negative contact, to get it to work. Pure Chinesium. Well, to be fair, they were a lot less expensive, and worked well other than that. My guess is they were tested with a different brand of battery.

The most surprising thing I learned about was the Phantom Voltage Divider.

I should explain. The battery holders I was using included a small circuit board, a CR2032 battery, a SPST switch, and metal contacts and traces. That’s it. No resistors or other electronics. Bare-bones simple.

So it was perplexing to put a 3V battery in and, with the switch off, measure 1.8V out. Changing voltages like that requires either active electronics or at the minimum, two resistors. There were no resistors anywhere on this board. What was happening?

Lack of sleep due to optimistic scheduling was what was happening. It turned out that the meter was correct. It really was reading 1.8V, and it was all my fault. Well, mine and the meter’s.

Multimeters (real ones) have a finite input impedance. This can be a calibrated high value of, for example, 10M ohms on professional desktop meters like the Agilent 34401A, or a similar, uncalibrated but high value on handheld meters. No doubt the Fluke that I was using has a well-understood input impedance. Or at least a high one.

Most of the time, this high impedance means that the meter won’t have a significant effect on the circuit voltage. What little current flows through the meter is lost in the (much greater) flow of current through the circuit.

This circuit was off, though — but still read 1.8V. Due to lack of sleep, it took me a few minutes to figure out the answer. I was the missing resistor. Part of my hand was in contact with the positive terminal on top of the battery, and a few microamps of current were leaking through my hand to the meter. Since the meter had roughly the same input resistance … it and I formed a voltage divider.

The laws of physics have a sense of humor, I guess.