Working with electricity can let you do some amazing things — like move objects around, produce, record, play back, and analyze signals of all kinds including audio and video, and even build computers and computer networks.

Unfortunately, electricity is not only useful, but invisible — which can make it difficult to see exactly what is going on in a circuit.

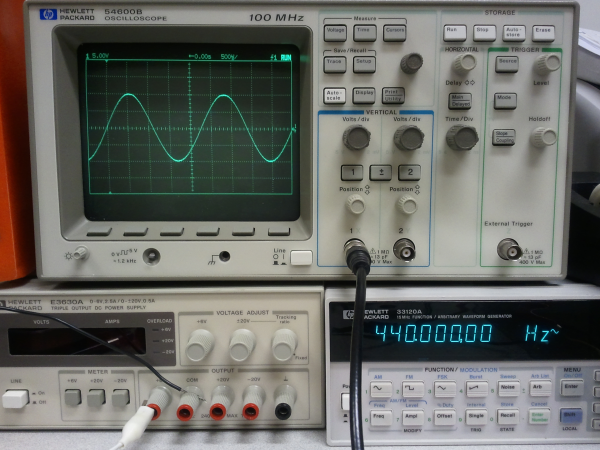

This is where oscilloscopes come in. An oscilloscope is a device which translates an electrical signal into an onscreen plot — usually, of voltage vs. time. The X (horizontal) axis generally represents time (increasing left-to-right), and the Y (vertical) axis generally represents voltage. Both of these can be scaled appropriately to show the features of the signal that you’re interested in.

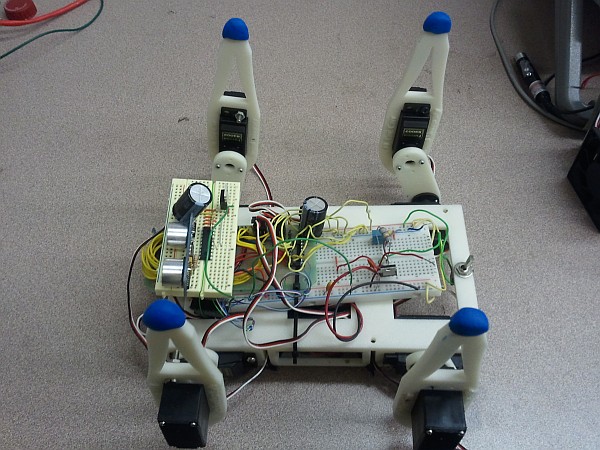

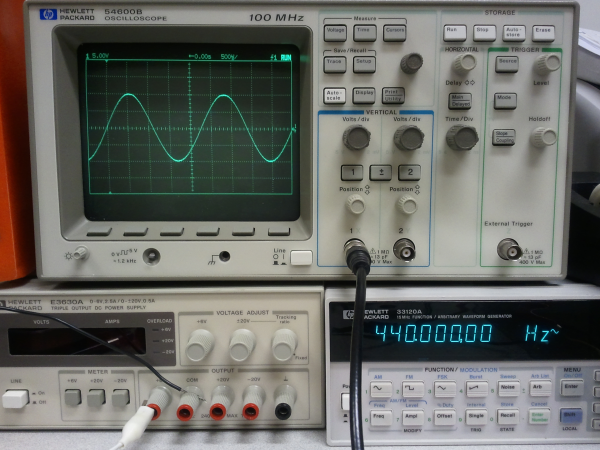

An oscilloscope, displaying a 440Hz sine wave from a signal generator. (Click for larger.)

There are many controls on a typical oscilloscope — which can make learning oscilloscope use somewhat intimidating, at first. Here are a few tips to help get you started:

- It’s (almost) impossible to damage the oscilloscope by setting the controls wrong. The worst that would generally happen is to set the ‘scope to settings that don’t make sense for displaying the signal you’re looking at. (This is assuming that the signal being fed into the oscilloscope is of a reasonable voltage.)

- There are four basic controls that you should become familiar with:

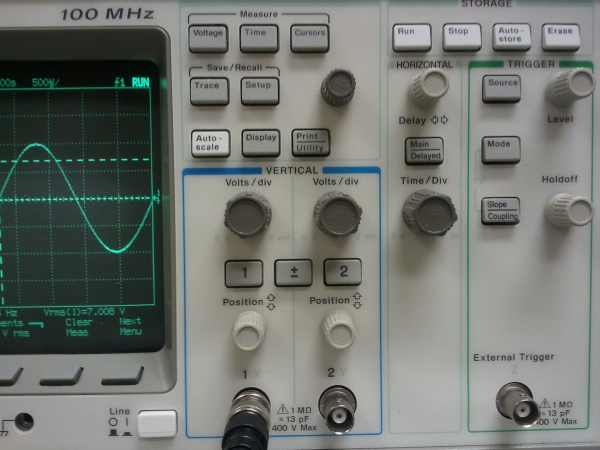

- The “Time/Div” control, which determines the speed of the sweep. Turn this knob clockwise to display faster signals (less time per horizontal division on the screen); turn it counterclockwise to display slower signals (more time per division on the screen.)

- The “Delay” control. This basically moves the display left and right, allowing you to see other parts of the signal. It has more functionality on a digital ‘scope because of differences in the way these ‘scopes work. (I plan on writing an article about the differences between digital and analog ‘scopes someday.) For now, think of this as a “pan” control which lets you view earlier or later parts of the signal on the screen.

- The “Volts/Div” control. This sets the vertical scale of the display. Turn this knob clockwise to display small-amplitude signals (fewer volts per vertical division on the screen); turn it counterclockwise to display large-amplitude signals (more volts per vertical division on the screen.) Remember that many oscilloscope probes include a voltage divider — typically 10:1 — and that this can make the displayed voltages appear smaller than they are, if the ‘scope doesn’t compensate for this.

- The “Vertical Position” control. This allows you to move the display up and down, centering the display on a higher or lower voltage. For instance, if you wanted to analyze a 1-volt sine wave that had a 3-volt DC bias, centering the display on +3 volts would allow you to increase the vertical gain and see smaller details of the signal.

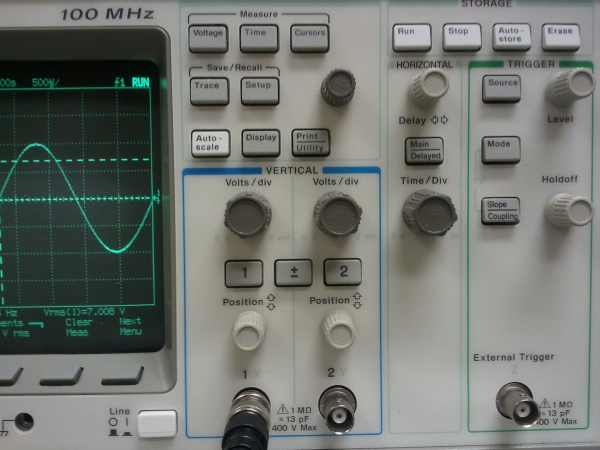

The controls of an HP 54600B digital oscilloscope. (Click for larger.)

Modern oscilloscopes have many other controls — including various trigger modes (the trigger function determines when the ‘scope starts drawing the plot across the screen); coupling modes (AC coupling inserts a series capacitance, removing DC bias from incoming signals); and many others, such as bandwidth limiting (for filtering out high-frequency noise).

One major benefit of modern digital oscilloscopes is the “Auto Scale” function (the white button just to the right of the screen on this ‘scope.) This “magic button” analyzes the incoming signals and makes an educated guess as to what display settings would work well. I find that it guesses right about 3/4 of the time — and the rest of the time, it usually focuses on one particular part of the signal — perhaps a noisy transition such as ringing noise on a square wave.

Also remember: “When in doubt, zoom out.” Set Volts/Div to a fairly high level (counterclockwise) and Time/Div to a slow speed (also counterclockwise). This will generally let you see the “big picture” and then zoom in as needed. Don’t overdo the Time/Div, though — at several seconds per division, it might seem like the ‘scope has stopped responding when it takes the better part of a minute to trace across the screen one time!