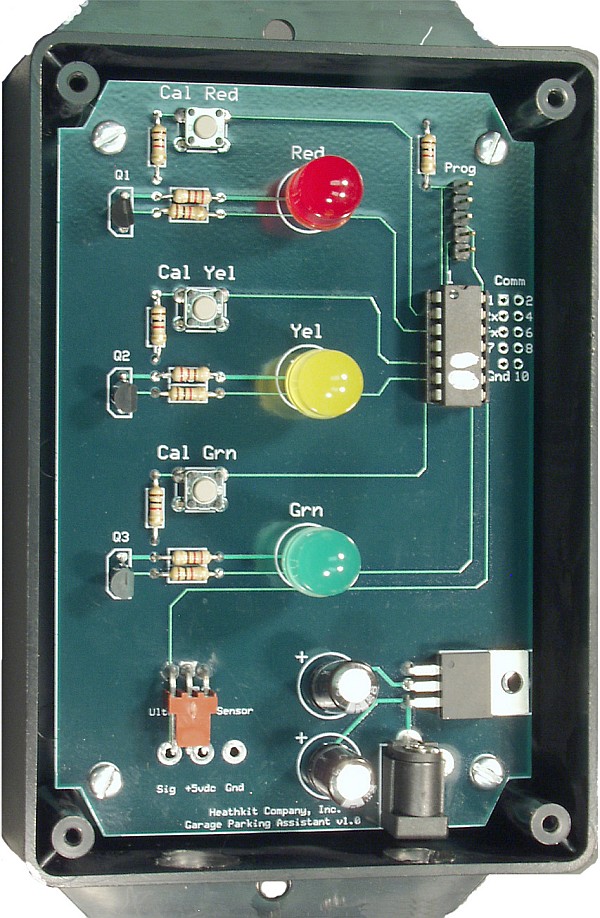

A nice side benefit to living in an increasingly technological age is the availability of interesting secondhand tech gear on sites like eBay. I recently came across a pair of Rubidium-based 10MHz atomic frequency standard modules for about $100 including shipping.

The Rubidium modules as seen in the eBay listing. (Click for larger.)

Rubidium frequency standard modules are considered by NIST to be secondary frequency standards — far more accurate and stable than most typical oscillators, including oven-controlled crystal oscillators — but not quite as stable as cesium-based units. Rubidium units have an accuracy of about 0.1 to 1.0 parts per billion. In other words, they would gain or lose just of a fraction of a second per decade.

The way they work is quite interesting: a rubidium lamp is used to produce light of a certain frequency (6.834682610904324 GHz), which corresponds to the time period of a transition between two specific hyperfine energy levels of rubidium atoms. This light passes through a chamber filled with gaseous rubidium before being sampled by a photodetector. A high-energy RF signal of around 6.8GHz is then applied to the chamber. This frequency tracks higher and lower by about 15-20 parts per million (PPM), until the photodetector senses a dip in the light being transmitted. Once this dip is sensed, it means that the applied frequency is the same as the resonance frequency of rubidium (the frequency match means that more photons from the Rubidium lamp are absorbed.)

A diagram of the rubidium frequency standard control loop. (Source: nist.gov)

When the frequency is locked (via a phase-locked-loop) to match this transmission dip, the applied RF frequency is known to be within a fraction of a part per billion of the resonance frequency of rubidium, which is known to very high accuracy. The frequency is then divided down to produce a very exact 10MHz reference signal.

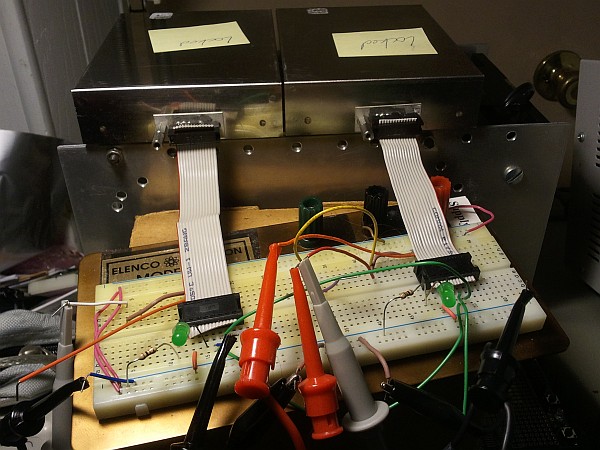

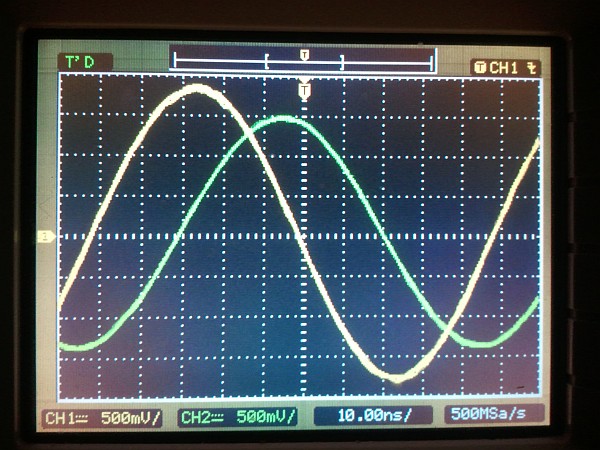

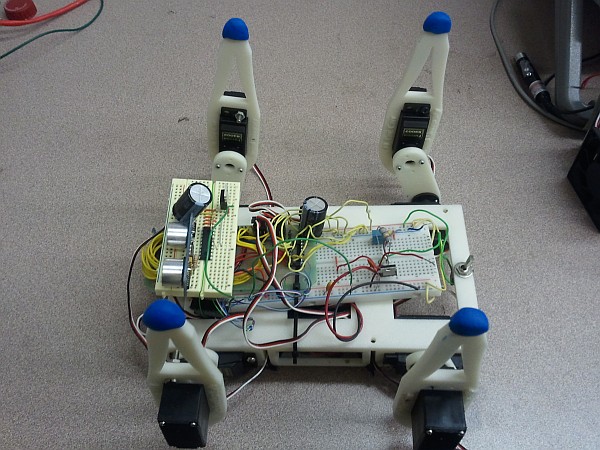

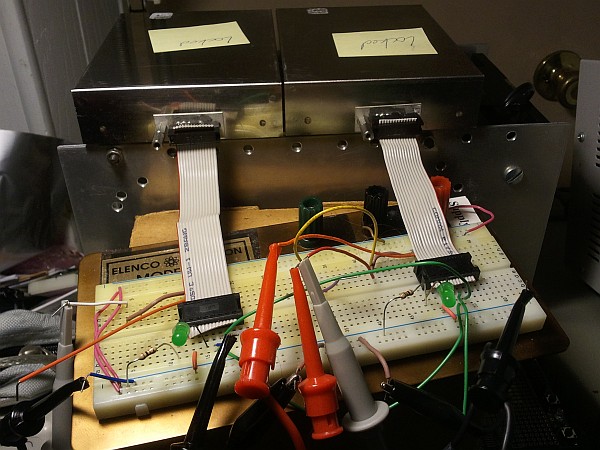

After a brief check, I set up the two modules; the requirements are surprisingly basic — just a 24V power supply. I then compared the two 10MHz output signals on an oscilloscope once both had achieved rubidium lock. It took 136 seconds for the difference between the two clock phases to drift by one cycle with respect to one another, starting a minute or two after the second one achieved lock.

Testing a pair of rubidium frequency standards. (Click for larger.)

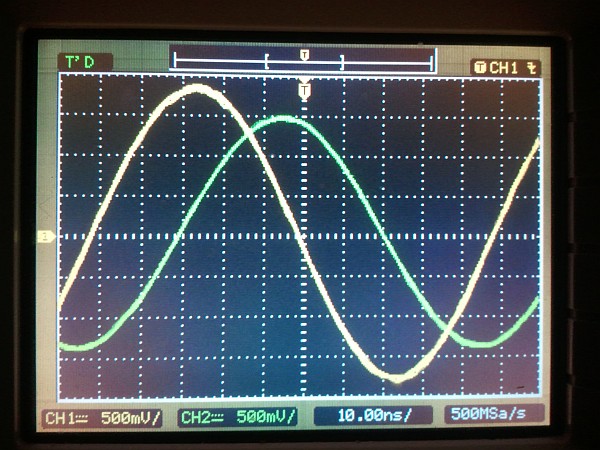

Viewing the phase difference between the 10MHz signals from both units. (Click for larger.)

After letting the clock modules run overnight, the time for one 360-degree phase shift between the two reference signals had lengthened to 400 seconds. At a signal rate of 10MHz, this means that the clock modules would disagree by one second for every 4,000,000,000 (four billion) seconds elapsed. In other words, running continually like this, they would disagree by one second every 126.75 years. (By contrast, the most accurate mechanical clocks gain or lose a second every year or two.)

Unfortunately, the downside of buying “as-is” units on eBay is that you often run into reliability problems. While both units do work and do achieve Rubidium lock (as the seller stated), the second unit has a very low rubidium lamp voltage (~2.43 volts). This indicates that it is near the end of its service life (the rubidium lamp has a finite lifetime). This explains why Unit 2 loses rubidium lock periodically (making it the equivalent of a rather oversophisticated crystal oscillator.) Amazingly, even without the rubidium lock, it still runs within 20PPM of the correct frequency — more than twice as stable as a typical TTL oscillator module. However, the rubidium phase lock is the whole point here: this provides roughly ten to twenty thousand times more accuracy.

According to the specifications I could find, healthy lamp voltages are in the 6-9 volt range, with higher being better (within reason). Fortunately, the first unit has a lamp voltage of around 8.9V, suggesting that it should be quite reliable. According to a technical note by the Datum corporation, the Rubidium package shouldn’t wear out, so the loss-of-lock problem may yet be manageable.

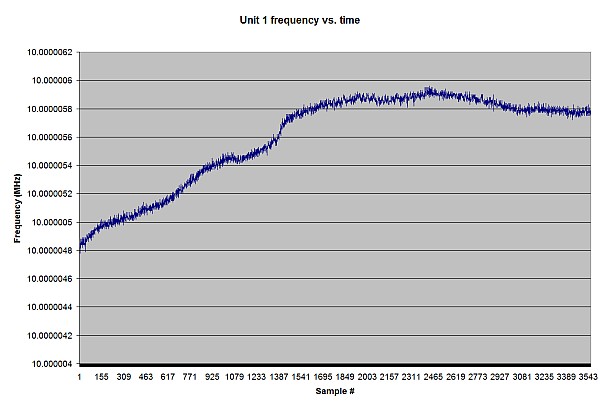

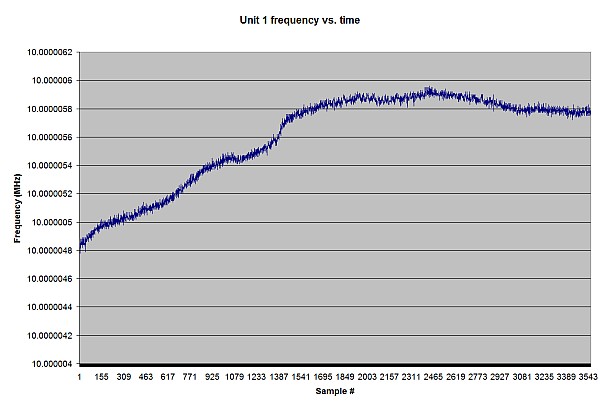

Unit 1, meanwhile, runs nicely — with a frequency variation of only about 1Hz out of 10MHz over an hour-long test run, according to my frequency counter.

Frequency drift -- probably mostly that of the frequency counter -- as measured over one hour. (Click for larger.)

I have cool plans for these little modules, once I either get the second unit to work reliably or find a replacement. With fraction-of-a-part-per-billion accuracy, all kinds of interesting experiments become possible, including investigating Einsteinian relativity. The first step is to make a management module, which would provide power, track number of pulses since reset, keep track of any loss-of-lock incidents, and monitor temperatures and voltages.